Charger Engineering Ltd. provides one stop in-house abilities that allow us to produce, re-produce, or re-manufacture all of your mechanical components. We have the qualified people and specialized shop equipment available for custom services.Our team has designed, manufactured and installed machinery under contract for some of the most recognized names in the industry, including Powell Equipment, Flare and many others. We are highly experienced in building and re-building machinery like edger’s, trimmers, carriages, saw fillers, log loaders or almost any component required in the resource industries. Providing OEM contract work for machinery components.

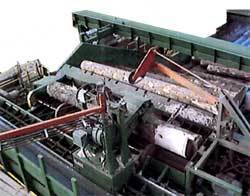

Review the photos below for detailed information of equipment we contract manufactured for Flare Sawmill Equipment.

Twin Bandmills

- Single Length Infeed

- Extended Length Infeed

- Double Length Infeed

- Adjustable Top Guide

- Can be Used in Resaw Applications

High Speed Board Edger

- Top Chipping (Sizing) Head

- Side Chipping Heads

- Hydraulic Feed Drive

- Chainbed Infeed

Circular Gangsaws

- Saw Lines to Suit

- Hydraulic Feed-roll Drive

- Extra Saw Guides

- Precision Saw Guide Re-surfacer

HS Series Bandmills

- Hydraulic Set works

- Digital Readout on Strain or Tilt

- Saw Guide Lubrication System

- Automatic Guide Positioning

Board Edger / Top Chipping Head

- Number of Knife Segments

- Number of Knives per Segment

- Chain Bed In-feed

Board Edger Optimizer

- Two, Three or More Chargers

- Hydraulic Feedroll Drive

- Hydraulic Cylinder on Clamp Points

- Chain Feed System

Twin Chipper Canters

- Finishing Saws

- Three or Six Knife Heads

- Feed Rolls

- Chromed Anvil

Cant Optimizer Infeed

- Sharp Chain Feed System

- Left or Right Hand Feed

- Hydraulic Feed Drive

- Double or Triple Pocket Feed

Curve Saw, Edger & Gang

- Up to Eight Saw Lines in Edgers

- Hydraulic Feed Roll Drive

- Extra Saw Guides

- Precision Saw Guide Resurfacer

- Infeed and Outfeed Tables

Multi-Saw Trimmer

- Number of Saw Ladders

- Individual Motors

- Metric or Imperial

- Adjustable Zero Saw

- Automatic Semi-Automatic or Manual Controls

Edger Resaw

- Hydraulic Feed Roll Drive

- Additional Saw Lines

- Extra Guides and Spacers

- Precision Sawguide Resurfacer

- Infeed System Designed to Suit

Log Carriage

- Compound Cylinder for Dog Opening & Closing

- Air Operated Cant Flipper

- Integrated Air Bag In Linear Positioner

- Soft Dogging Air Circuit

2 or 4 Saw Scragg

- Four Saws in Tandem or Parallel

- Hydraulic Feed Drive

- Sharp-Chain Through Saws

Log Merchandising System

- Alternative Flow Configurations

- Log Sort Bins

- Number of Saws

Flare Butt Reducers

- Can be Combined with Log Sizer

- Double End Units

- Infeed and Outfeed Configurations

Log Sizers

- Can be Combined with Butt Reducer

- Infeed and Outfeed Configurations

Circular Saw Guide